-

MOQ and Shipping Quantities by Product

Item # 6100 | Part # FWRC-4-White | 500 PC MOQ | Orders above MOQ: 250 PC per box

Item # 6101 | Part # FWRC-4-Blue | 500 PC MOQ | Orders above MOQ: 250 PC per box

Item # 6102 | Part # FWRC-4-Yellow | 500 PC MOQ | Orders above MOQ: 250 PC per box

Item # 6103 | Part # FWRC-6-Blue | 500 PC MOQ | Orders above MOQ: 250 PC per box

Item # 6104 | Part # FWRC-6-White | 500 PC MOQ | Orders above MOQ: 250 PC per box

Item # 6105 | Part # FWRC-6-Yellow | 500 PC MOQ | Orders above MOQ: 250 PC per box

Item # 6106 | Part # FWRC-12-Blue | 500 PC MOQ | Orders above MOQ: 100 PC per box

Item # 6107 | Part # FWRC-12-White | 500 PC MOQ | Orders above MOQ: 100 PC per box

Item # 6113 | Part # FWRC-12-Yellow | 500 PC MOQ | Orders above MOQ: 100 PC per box

-

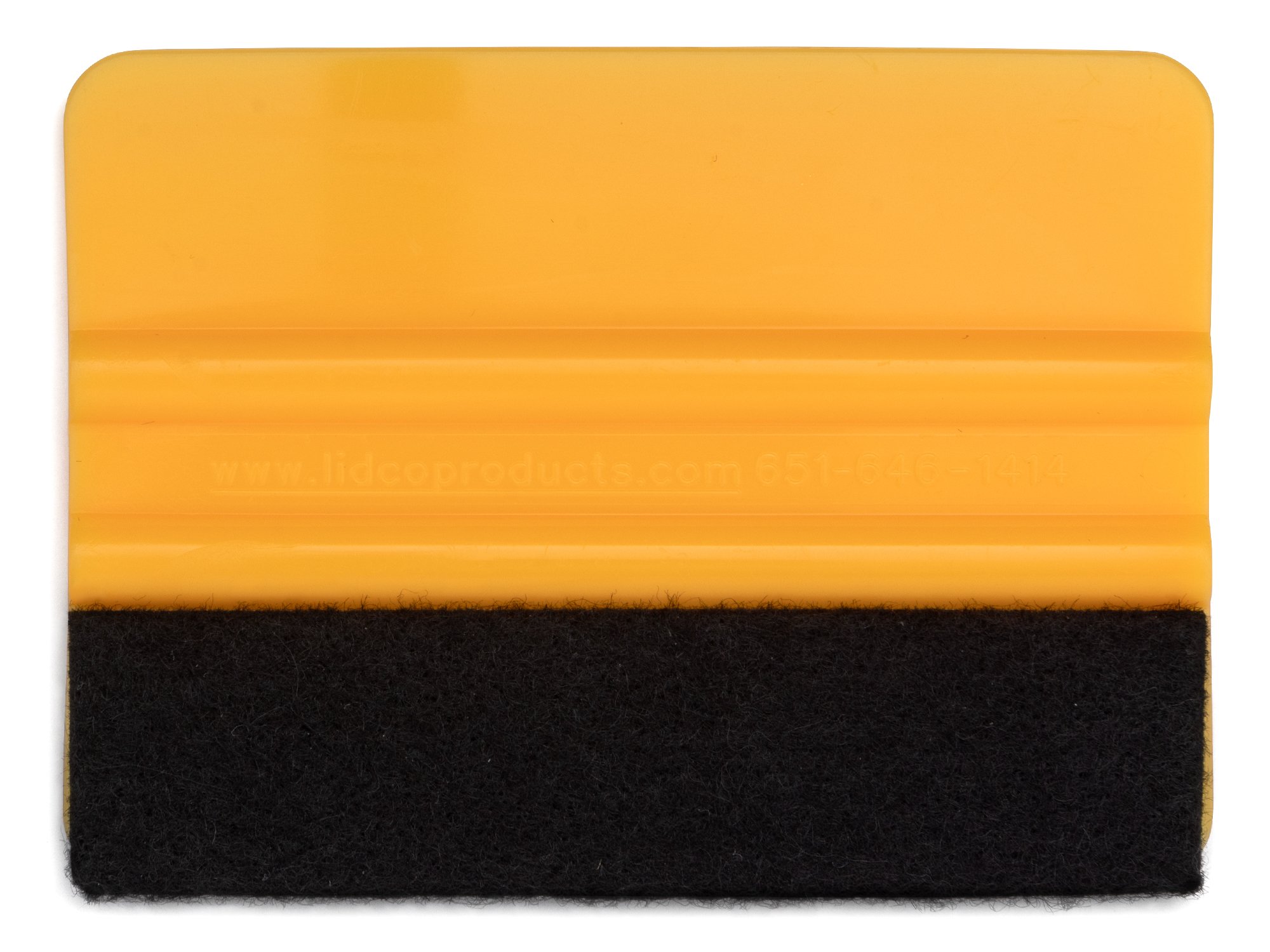

A felt edge wrapped squeegee allows installers to apply pressure without damaging the vinyl or substrate. The Lidco Standard-Weight Felt Edge Wrapped Squeegee delivers the ideal balance between firmness and surface protection, making it a go-to tool for professional installers and DIY users who want clean, scratch-free results on every job.

-

A felt edge squeegee is a poly hand tool designed to smooth and apply thin films, vinyl graphics, decals, and similar materials without scratching or damaging the surface. Pre-applied soft felt edge protects sensitive finishes while allowing firm pressure to remove air bubbles and ensure a clean, even adhesion.

-

A felt-wrapped squeegee integrates the protective felt directly on the tool, eliminating the need for separate felt strips or tape. This saves time and enhances control, ensuring a smooth, scratch-free installation every time.

-

A felt edge squeegee is generally better suited for vinyl work than a standard poly squeegee when surface protection and finish quality are priorities. The key difference lies in how each tool interacts with the vinyl and the substrate:

Felt edge squeegee: The soft felt lining cushions the contact between the tool and the vinyl film. This significantly reduces the risk of scratching, marring, or lifting the vinyl surface, especially on sensitive finishes like paint protection film (PPF), window tint, decals, and automotive wraps. The felt also helps the tool glide smoothly, making it easier to work around contours, curves, and edges without damaging the vinyl.

Standard poly squeegee: A poly (plastic) squeegee has a harder edge that can exert more force on the film. This is acceptable for heavier-duty tasks such as initial water and air removal or adhesion on rigid substrates. However, without a protective buffer, a poly edge can more easily leave marks, stretch the vinyl, or create visible tool lines if not used with great care.

Conclusion: For most vinyl installation tasks—especially final finishing, delicate surfaces, and graphic work—a felt edge squeegee provides a safer, more forgiving option than a standard poly squeegee. A poly squeegee still has a place in your kit for heavier bond or initial lay-down, but the felt edge is usually preferred when quality of finish and surface protection matter.

-

The lifespan of the felt edge on a squeegee depends on how frequently it’s used and the conditions of use. With regular use on smooth surfaces and proper care, the felt edge typically lasts for many weeks to several months for professional installers. Factors that affect longevity include:

Surface conditions: Rough, gritty, or contaminated surfaces wear felt faster than clean, smooth ones.

Pressure and technique: Excessive force or aggressive strokes can abrade the felt more quickly.

Cleaning and maintenance: Wiping the felt clean after use and storing the tool properly extends its life.

Over time the felt may become compressed, frayed, or saturated with debris, at which point performance—especially glide and surface protection—can diminish. When you notice decreased smoothness or visible wear, it’s a good indication that it’s time to replace the squeegee or felt wrapping.